Introduction

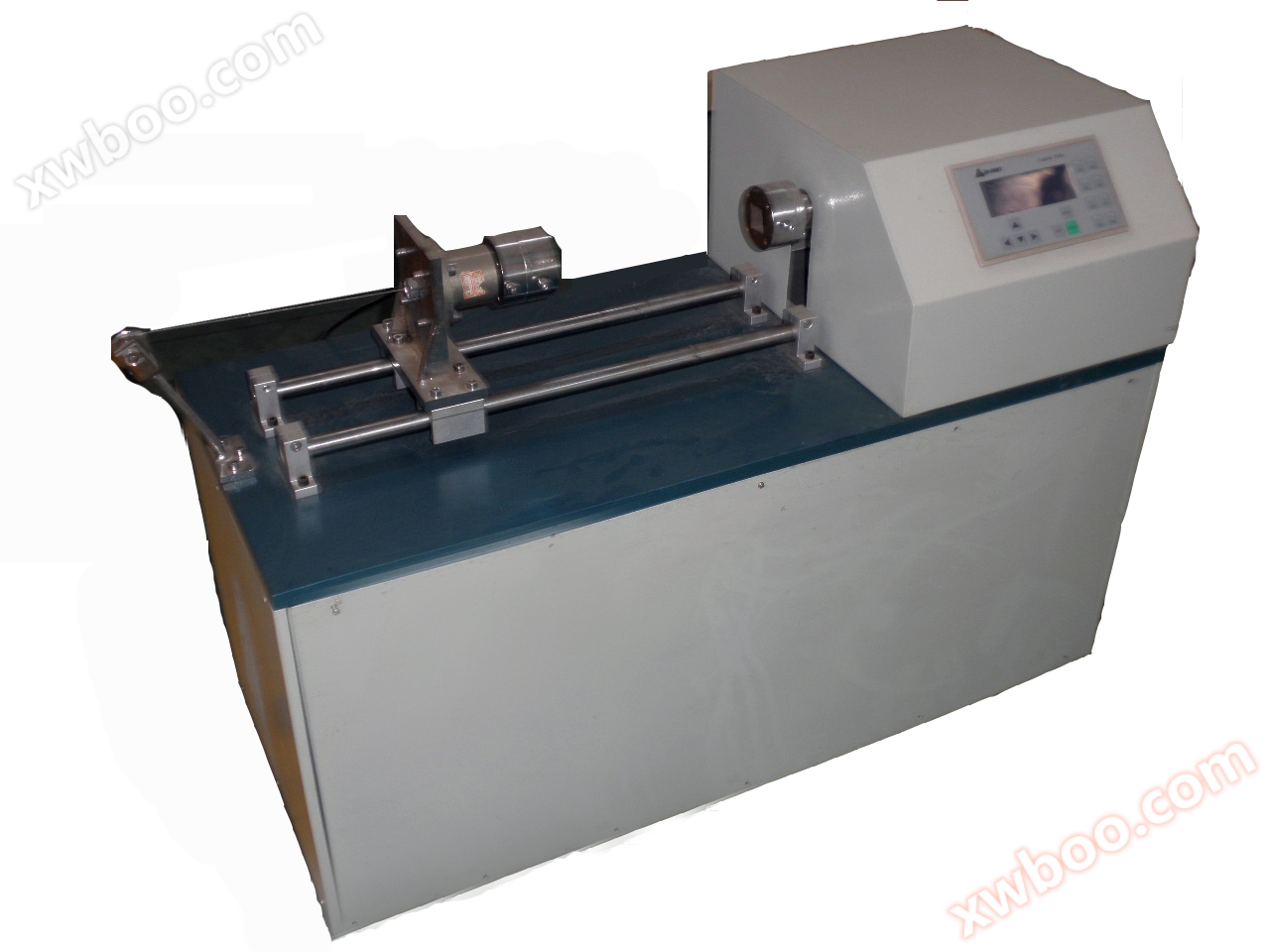

The computer-controlled wire torsion testing machine is widely used for material inspection and analysis in industries such as building materials, aerospace, machinery manufacturing, wire and cable, rubber and plastic, automotive manufacturing, shock absorption systems, etc. It is an ideal testing equipment for scientific research institutions, colleges and universities, industrial and mining enterprises, technical supervision, commercial inspection and arbitration departments

Functions and characteristics of computer-controlled wire torsion testing machine

The testing machine has two rotation speeds of 30 and 60 revolutions per minute, which can be adjusted by a switch. The length of the clamping wire can be 500-300mm, and the axial force is increased by a 10:1 lever with dynamic force. When in place, the rotating motor is automatically started for testing, and the machine stops automatically after the specimen breaks. The number of test cycles is displayed by a 4-digit LED digital tube, with a large display of 999.9 cycles. After the specimen breaks, the test cycle value is automatically blocked

Equipment configuration of computer-controlled wire torsion testing machine

One high-strength torsion host

Two sets of AC servo speed control system and one set of AC servo speed control motor

Two sets of ABBA precision guide rails from Taiwan

A set of 4 precision deceleration systems

5 high-precision torsional sensors

6 sets of specialized twisting and supporting aids

A set of dedicated test measurement and control display system for torsion testing machine

Main technical parameters

Metal wire clamping range: Φ 0.1mm-3.0mm

Gauge distance between two clamps: 350mm

Speed: 0-300r/min

Torque resolution accuracy: 0.001N. m

Coaxiality of two clamps: < Φ 0.4

Power supply: 220V 50HZ

Weight: 120kg

Dimensions: 980 × 400 × 650 (mm)